Home > Products > Ultrasonic Wall Measurement > Ultrasonic Thickness Measurement Sensor Assemblies

Ultrasonic Thickness Measurement Sensor Assemblies

Ultrasonic thickness sensors

with fixed mounting

Resources

Ultrasonic wall, concentricity, and eccentricity measurement

Product safety standards (e.g. CE, UL)

LaserLinc’s line of UltraGauge+™ sensor assemblies provide continuous wall thickness measurement for round products such as medical tubing, insulated wire and cable, hose, pipe, and metal and glass tubing.

Realize significant savings due to faster startup cycles, reduced material usage and scrap, and improved product quality. These objectives are easily achieved when armed with real-time, precise wall and concentricity measurement.

LaserLinc’s UltraGauge+ product line accommodates a wide range of product diameters and material thicknesses. Different styles and options cover fixed and adjustable transducer positioning, vacuum tank installation, product guiding options, and up to eight transducers.

Keys to Successful Wall Thickness Measurement

The keys to successful ultrasonic wall thickness measurement equipment include:

- Proper alignment of the transducers with the product you are measuring

- Elimination or purging of air bubbles as air attenuates ultrasound

- Intelligent and sophisticated signal analysis techniques

- Ease of operator use

UltraGauge+ sensor assemblies embody LaserLinc’s years of experience and hundreds of installations.

Sensor Assembly Styles

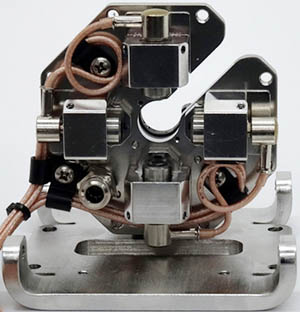

Sensor assemblies come in two basic styles: a donut-shape (ring) or a C-shape construction.

The ring style is usually mounted to the entry or exit wall of a vacuum tank or cooling trough as this has virtually no impact on how the operator “strings the line.” Typically, product position is well constrained at these points so product alignment is virtually automatic.

C-style fixtures have an opening for threading the product without a break. Alternatively, it allows the fixture to be inserted or removed without breaking the product.

A third style is a variation of a ring: a self-contained design for inspection of cut-to-length tubing and in-process measurement where contact with water must be kept to an absolute minimum. The fixture is very small so it’s portable for QC use and fits in tight spaces on the production line.

C-style configuration

Guides and Sensor Alignment

Various guides are available to ensure proper alignment of the transducers with the product: adjustable tension roller guides, clamshell guides, and horizontal/vertical adjustment for the sensor assembly itself. Some guides are designed to break away if a slub, lump, gel, knot, or other significant defect strikes the fixture. Guides can be used with either ring or C-shape fixture styles.

Vacuum Tank Installation

The closer the wall and concentricity measurements are made to the extruder, the faster the system can correct for wall thickness variation and the easier it is to adjust tooling to achieve concentricity targets.

In many processes, the place nearest to the extruder in which the sensor can be installed is in the vacuum tank. However, once under vacuum, it is often necessary to tune the alignment of the sensors with the product. LaserLinc offers a simple mechanism for installation in a vacuum tank with easy external vertical and horizontal adjustment, leaving the vacuum unaffected.

Transducers

Four transducers are typical in a sensor assembly and provide sufficient feedback for accurate average wall thickness measurement and optimizing concentricity. In cases where the wall thickness specification is critical, six or eight transducers provide additional inspection points to ensure adherence to specifications.

All assemblies protect the transducers from coming into contact with your product. Transducers are set back from the pass-through for the product and each has directed water flow across its face to purge any air bubbles or particles.

Click here for a table of transducer frequencies offered by LaserLinc with associated measurement ranges.

Accessories and Custom Sensor Assemblies

LaserLinc designs special accessories and sensor assemblies to operate in unusual process environments, under atypical physical space constraints, on non-round product profiles, or those with unique material properties. Contact LaserLinc staff to discuss your specific needs.

If you do not want to, or cannot, install the ultrasonic sensor assembly in an existing tank, LaserLinc offers small tanks designed to fit most production lines. The tanks have plumbing for easy drain and fill, optional guides, and an optional sight glass for viewing the product as it passes.

Sensor Assembly Highlights

- Measure clear or opaque plastic, rubber, glass, and metal products

- Measure up to 4 layers

- Measure up to 2000 times per second

- Repeatability down to ±.000040" [±1μm]

- Measure wall thickness down to .001” [25μm] and up to over 1 inch [25.4mm], by configuring with selected transducer frequencies

- All transducer assemblies integrate water flow to keep transducers free of air bubbles and debris for reliable, continuous operation

- Transducers are set back from product path and protected for lasting use

- All assemblies tie into the UltraGauge+ digital signal processor (DSP) for sophisticated signal processing and precision measurement, with Total Vu™ software as the user interface

- Choose from many different sensor assembly configurations for optimal use with your particular product and process: ring or C-shape construction, guiding, mounting, and number of transducers

- Unique self-contained style is available for cut-to-length products, applications requiring an absolute minimum of contact with water, and portable use

- Accessories available for turnkey installation